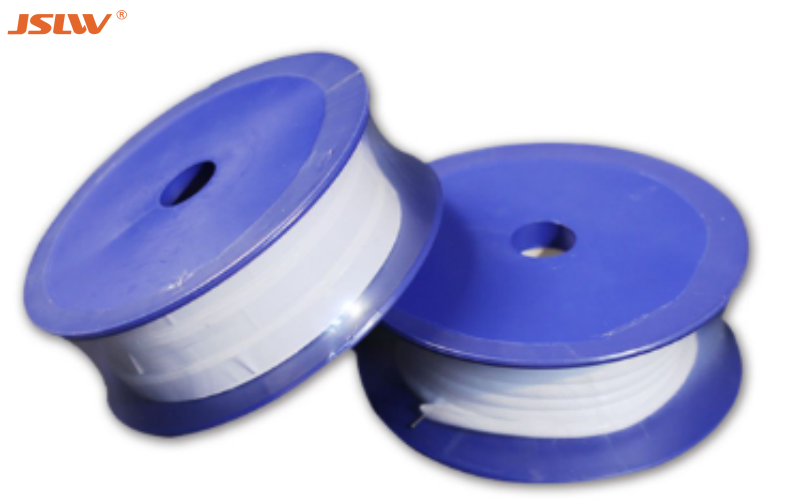

In the intricate systems of modern industry, sealing materials may seem inconspicuous, yet they are crucial for ensuring the efficient operation of equipment. Among them, PTFE elastic tape is quietly becoming the material of choice in many demanding applications due to its exceptional performance. This elastic sealing tape, processed through special techniques from polytetrafluoroethylene (PTFE), plays an irreplaceable role in various fields. Let’s explore where it excels.

Core Application Areas of PTFE Elastic Tape

1. Corrosion-Resistant Sealing in Chemical and Pharmaceutical Industries

In highly corrosive environments, traditional sealing materials often fail quickly. Thanks to its outstanding chemical inertness, PTFE elastic tape can withstand erosion from most strong acids, alkalis, and organic solvents. It is widely used for sealing reactors, pipeline flanges, pumps, and valves. In the pharmaceutical industry, its dual advantages of cleanliness and corrosion resistance make it a reliable choice for production lines adhering to GMP standards.

2. Hygienic Applications in Food Processing and Packaging Equipment

PTFE elastic tape, compliant with FDA food contact standards, does not contaminate products and is odorless and tasteless. It performs exceptionally well in sealing food processing equipment, filling lines, and packaging machinery. Its smooth, non-stick surface is easy to clean and effectively prevents bacterial growth, meeting the stringent hygiene requirements of the food industry.

3. Ultra-Pure Environments in Semiconductor and Electronics Manufacturing

High-end electronics industries, such as wafer manufacturing and flat-panel display production, require extremely high levels of cleanliness. PTFE elastic tape not only has minimal outgassing but also effectively isolates external contaminants. It is used for sealing critical areas like vacuum chambers and specialty gas delivery pipelines, ensuring ultra-high purity in production environments.

4. Weather-Resistant Sealing in Energy and Power Industries

Whether in the salty spray environments of offshore wind power equipment or the temperature fluctuations of petrochemical installations, PTFE elastic tape maintains stable sealing performance. Its wide temperature tolerance range (-200°C to +260°C), combined with excellent anti-aging properties, ensures long-term reliability even under harsh climatic conditions and extreme temperature variations.

5. High-Performance Applications in Aerospace and Automotive Industries

In engine systems, fuel pipelines, and hydraulic devices, PTFE elastic tape provides a lightweight, high-temperature-resistant sealing solution. Its low friction coefficient and self-lubricating properties make it particularly suitable for critical locations requiring precise control and minimal maintenance.

Why Choose PTFE Elastic Tape?

Compared to traditional sealing materials like rubber, cork, or graphite, the advantages of PTFE elastic tape are clear:

Extremely Broad Chemical Compatibility: Resistant to almost all industrial chemicals.

Wide Temperature Range: Maintains elasticity from cryogenic to high temperatures.

Excellent Anti-Aging Performance: Resistant to UV rays, ozone, and weather aging.

Outstanding Mechanical Properties: Good compression resilience and anti-creep ability.

Compliance with Stringent Standards: Meets the specific requirements of the food, pharmaceutical, and electronics industries.

Conclusion

PTFE elastic tape may seem like a small component in the industrial field, but it plays a critical role as a “small material with big impact.” From ensuring the safe operation of chemical plants to guaranteeing the flawless manufacturing of every chip; from safeguarding food safety on our tables to supporting the efficient operation of clean energy facilities—PTFE elastic tape silently guards the “boundaries” of modern industry with its “elastic” presence.

As material science continues to advance, the application boundaries of PTFE elastic tape will further expand. When selecting sealing solutions, understanding the unique properties and applications of this material may provide the perfect “key” for your next project. In the world of precision industry, it is often these unseen details that determine the success or failure of system operations.