In industries such as semiconductor manufacturing, chemicals, and life sciences, the purity, corrosion resistance, and reliability of fluid handling systems are paramount. Among the many material options available, Polytetrafluoroethylene (PTFE) and Perfluoroalkoxy (PFA) stand out due to their exceptional chemical inertness and high-temperature resistance. Both belong to the Teflon family, often referred to as the “kings of plastics,” and share similar appearances and overlapping properties. However, it is their subtle differences that determine the success or failure of an application. Faced with the choice between PTFE tubing and PFA tubing, many engineers and purchasers find themselves wondering: How do I make the correct choice? This article will provide a clear, practical guide by delving into a detailed comparison of these two materials.

PTFE (Polytetrafluoroethylene)

Advantages:

Unmatched Chemical Inertness: Resists attack by virtually all chemicals, including strong acids, strong bases, and even aqua regia. It is the gold standard for chemical inertness.

Highest Temperature Rating: Continuous service temperature up to 260°C, with even higher short-term tolerance.

Lowest Coefficient of Friction: Its very smooth, non-stick surface is advantageous for handling viscous fluids.

Disadvantages:

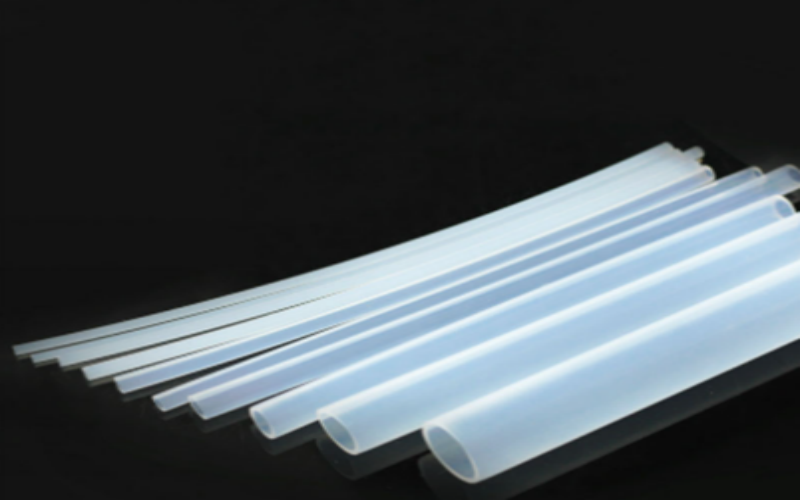

Opaque: Typically white and not transparent

Difficult to Process: Cannot be melt-processed like conventional plastics. It is manufactured using a sintering technique, which can result in a stiffer tube with potential micro-porosity.

PFA (Perfluoroalkoxy)

Advantages:

High Chemical Purity: Offers chemical resistance comparable to PTFE, handling most aggressive chemicals.

Excellent Transparency: Can be manufactured as highly transparent or semi-transparent tubing, allowing for visual monitoring of fluid flow and internal cleanliness.

Ease of Processing: It is a melt-processable fluoropolymer. This allows for extrusion into tubing with a very smooth, non-porous, and contaminant-free inner surface.

Disadvantages:

Higher Cost: Raw material and processing costs are generally higher than those of PTFE.

Slightly Lower Mechanical Strength: PTFE may be more suitable in very high-pressure environments.

How to Make the Right Choice? Key Decision Factors

With the basic properties outlined, you can determine the best choice by answering these key questions:

1.Does your application require “seeing is believing”?

Visual Monitoring Required: If you need to visually monitor fluid flow, check for bubbles, particulate contamination, or color changes inside the tube, choose PFA Tubing. Its transparency is an unmatched advantage, crucial in semiconductor ultrapure water systems and biopharmaceutical processes.

No Visual Monitoring Needed: If the tube is merely a conduit and appearance doesn’t matter, both PTFE and PFA can be considered.

2.What are the characteristics of your fluid?

Ultrapure Fluids or Highly Sensitive Chemicals: While both are chemically inert, PFA tubing’s non-porous, super-smooth inner wall is superior for maintaining the purity of fluids like ultrapure water and high-purity chemicals. It is also easier to clean. PFA is often the preferred choice in semiconductor and life science industries.

Standard Corrosive Chemicals: For handling most strong acids and bases, PTFE tubing is fully capable and more cost-effective.

3.How complex is your tubing layout?

Compact Space, Multiple Bends: If the installation space is tight and requires tight bending radii, PFA tubing is the better choice due to its superior flexibility. It can easily handle complex routing and is less prone to cracking or deforming under stress.

Straight Runs or Large Bend Radii: If the tubing path is relatively straight, PTFE tubing will work fine, but be mindful of its “memory effect” during installation.

Conclusion

In summary, let your application scenario—chemical environment, temperature, purity requirements, physical layout, and budget—be your guide. By carefully weighing these factors, you can confidently select the most suitable member of this exceptional fluoropolymer family. The right choice ensures not only smooth process operation but also the safety of your production and the quality of your final product.