Choosing between rubber gaskets and metal gaskets is a classic engineering problem. There is no absolute “better”, only “more suitable”. This blog will guide you step by step to clarify your thoughts and make the best choice for your specific application.

Key Introduction:

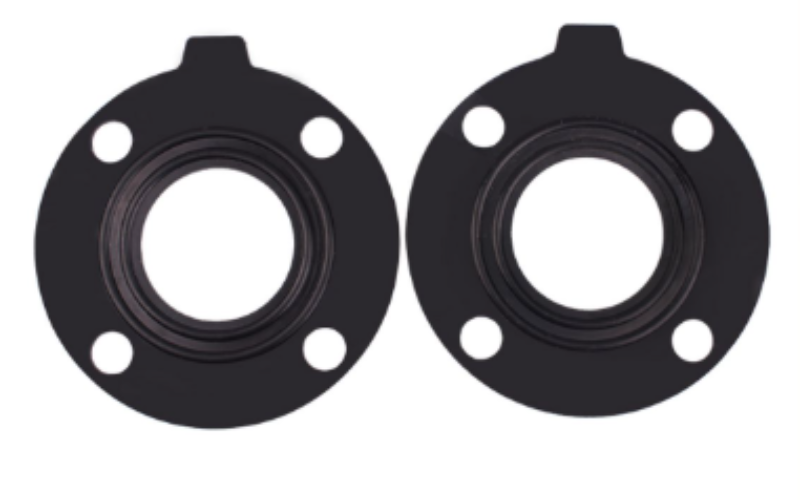

Rubber gasket: It fills uneven surfaces through elastic deformation to achieve soft sealing and is suitable for conventional working conditions with medium and low pressure and low to medium temperatures.

Metal gaskets: They rely on the strength and resilience of the material to withstand extremely high pressure and temperature, achieving a hard seal. They are suitable for extreme working conditions such as high temperature, high pressure, and strong corrosion.

Quick Comparison: Rubber vs. Metal Gaskets

| Aspect | Rubber Gaskets | Metal Gaskets |

| Sealing Principle | Soft Seal, elastic deformation | Hard Seal, high bolt load required |

| Pressure | Low – Medium Pressure | Medium – Ultra-High Pressure |

| Temperature | (-60°C ~ +250°C) | (-200°C ~ +1000°C+) |

| Media Resistance | Varies by compound, can be susceptible | Excellent, wide alloy selection |

| Recovery | Good, handles fluctuations | Poor, prone to relaxation (except spiral-wound) |

| Flange Surface | Low requirement, forgiving | High requirement, must be smooth/hard |

| Cost | Low – Medium | Medium – High |

| Common Types | O-rings, flat gaskets, silicone gaskets | Spiral-wound, Ring Joint, Metal Jacketed |

How to choose?

Step 1: Clarify the working conditions (this is the most important factor)

1.What is a medium? (Chemical resistance)

Water, air, oil, fuel, chemical solvents, strong acids/strong bases?

Select rubber: The rubber material that matches the medium should be chosen.

Metal selection: For most chemical media, especially those with strong corrosiveness, metals usually have more advantages.

2.What is the temperature range? (Temperature resistance)

Select rubber: Common rubber (such as NBR) will become brittle or melt at this temperature. Even high-performance silicone or fluororubber has an upper limit (usually not exceeding 300°C).

Choose metal: This is the domain of metal gaskets. Stainless steel can easily withstand temperatures ranging from 500 to 700°C, while nickel-based alloys can endure temperatures above 1000°C.

3.What is the pressure range? (Pressure resistance)

Is the system pressure above 15-20 MPa? Are there any severe pressure fluctuations?

Rubber selection: Under high pressure, rubber gaskets are prone to being “squeezed out” into the flange gap, leading to permanent damage and leakage.

Metal selection: Metal gaskets (especially metal wound gaskets) are designed to resist extrusion and can withstand extremely high pressure.

Step 2:Consider the flange conditions and installation

Flange surface quality:If there are slight scratches or unevenness on the flange surface, the elasticity of the rubber gasket can compensate well. Metal gaskets require a smooth and flat surface to seal effectively.

Bolt load: Metal gaskets (solid metal gaskets) require a very large bolt torque to undergo plastic deformation and achieve sealing. If the structure cannot provide such a large clamping force, rubber gaskets or metal wound gaskets that require a smaller bolt force should be selected.

Disassembly frequency: If frequent disassembly and maintenance are required, rubber gaskets are usually disposable and need to be replaced after disassembly. Some metal gaskets (such as solid metal ring gaskets) can be reused when used correctly.

Step 3: Weigh costs against the life cycle

Initial cost: Standard rubber gaskets are usually the cheapest.

Life cycle cost: Under harsh working conditions, cheap rubber gaskets may fail quickly. At this point, choosing more durable but more expensive metal gaskets is actually more economical.

Examples of typical application scenarios

Situations where rubber gaskets are selected:

Automotive industry: Engine oil pan gasket, headlight sealing ring, radiator interface.

Common pipelines: Flange connections for water and air pipelines.

Situations where metal gaskets are selected:

Petrochemical industry: Reactors, high-temperature and high-pressure pipeline flanges

Power station: Steam turbine, boiler system.

Aerospace: Engine pipelines, fuel systems.

Hybrid gasket: The best compromise solution

When you need the sealing property of rubber and the strength of metal, you can consider hybrid gaskets, the most typical of which is the metal wound gasket.

Structure: It is composed of alternately wound metal strips (such as 304 stainless steel) and soft filling materials (such as graphite, PTFE).

Conclusion:

Rubber gaskets are an economical and versatile choice for handling conventional working conditions, achieving soft sealing through elasticity. Metal gaskets are a high-performance and highly reliable choice for extreme working conditions, achieving hard seals through strength and plastic deformation.